Material and processing

Our capabilities

Processing expertise and a modern, wide range of machines are the key to implementing our customers’ requirements perfectly. We therefore think it is very important to make regular investments in the machinery and continuous training for our employees.

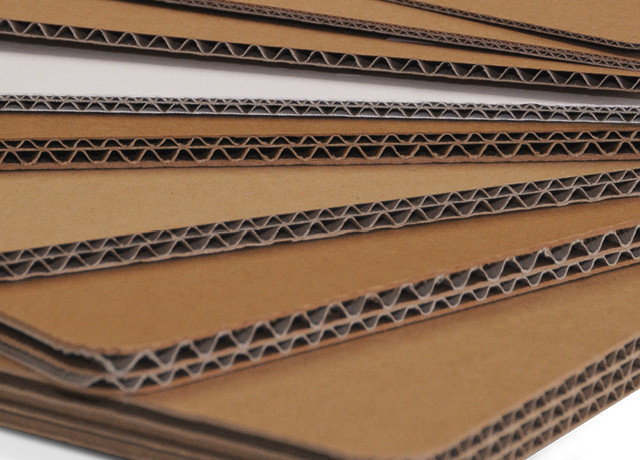

We are able to offer a wide range of different corrugated board grades and varieties depending on what the customer requires. You can choose from light, 1-wall grades for small packages or 2-wave corrugated board varieties with high load-bearing capacity and a buffering effect. We also have 3-wave heavy-duty corrugated board as a substitute for wood or overseas-compatible containers in our range.

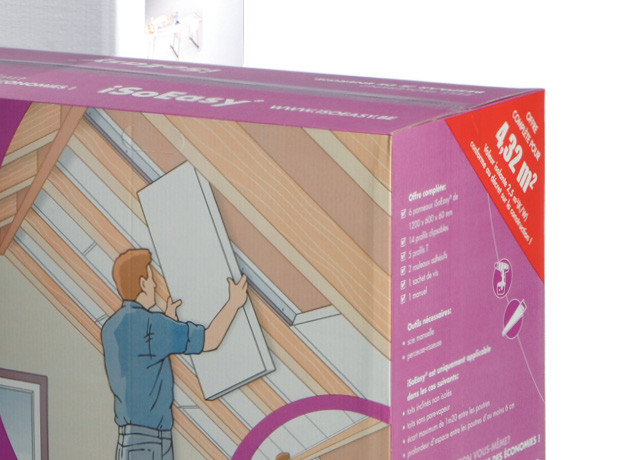

Photorealistic offset printed sheets can be applied to all packaging over the full area or part of the surface.

All printed images can be produced with the traditional printing method for corrugated board. From a simple logo print and halftone prints with three colours through to photorealistic motifs, all design variants are possible.

All printed images can be produced with the traditional printing method for corrugated board. From a simple logo print and halftone prints with three colours through to photorealistic motifs, all design variants are possible.

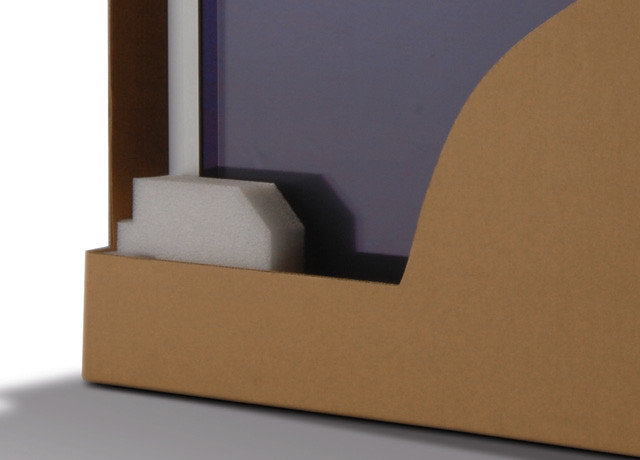

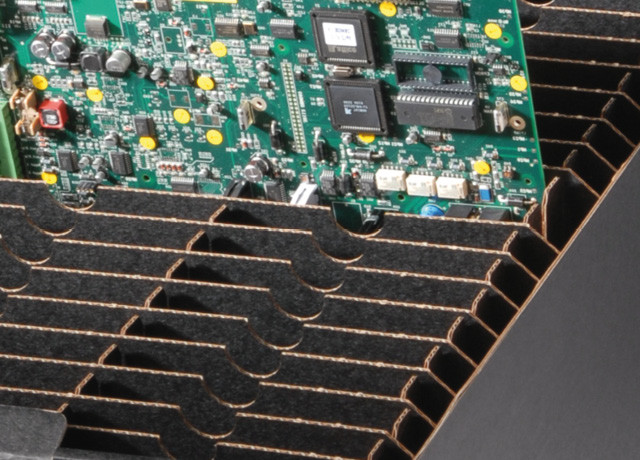

Highly sensitive equipment requires a special level of protection which can only be guaranteed by using foam padding which is individually customised to suit the particular product. Engineered foams offer calculable and certifiable compression and cushioning properties for this.

Highly sensitive equipment requires a special level of protection which can only be guaranteed by using foam padding which is individually customised to suit the particular product. Engineered foams offer calculable and certifiable compression and cushioning properties for this.

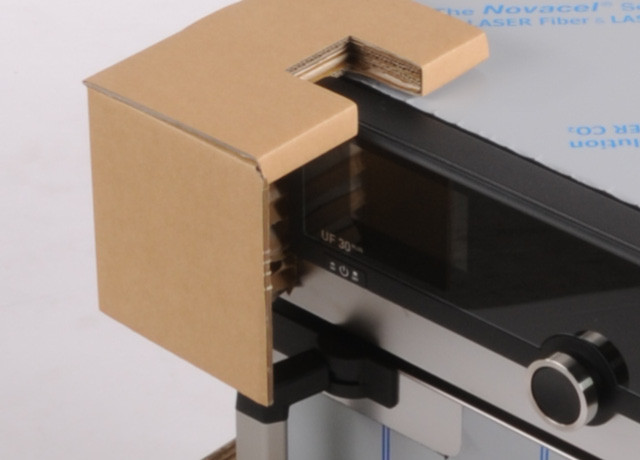

Prefabricated, securely glued pads are individually adapted to fix the products in place. They provide ideal protection at edges and corners and a secure hold, particularly for heavy products.

Prefabricated, securely glued pads are individually adapted to fix the products in place. They provide ideal protection at edges and corners and a secure hold, particularly for heavy products.

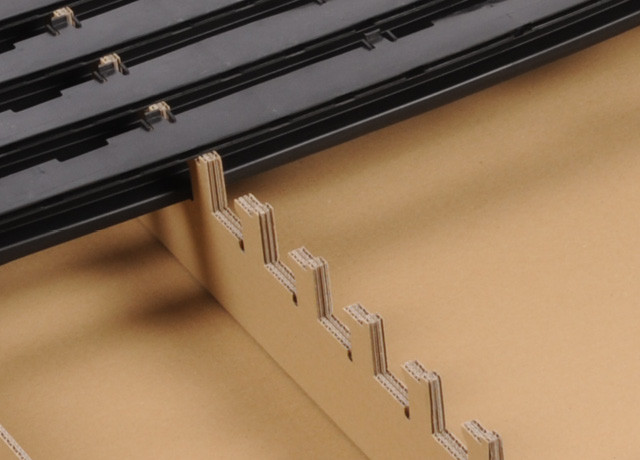

Optimum sorting along with the very best stackability thanks to even load distribution. Each individual part is safely protected all the way round.

You can choose either a normal compartment or a shaped compartment. Your product is securely fixed in place to prevent it from slipping and safely protected on all sides. In addition, a compartment guarantees a high packing density and outstanding stacking properties.

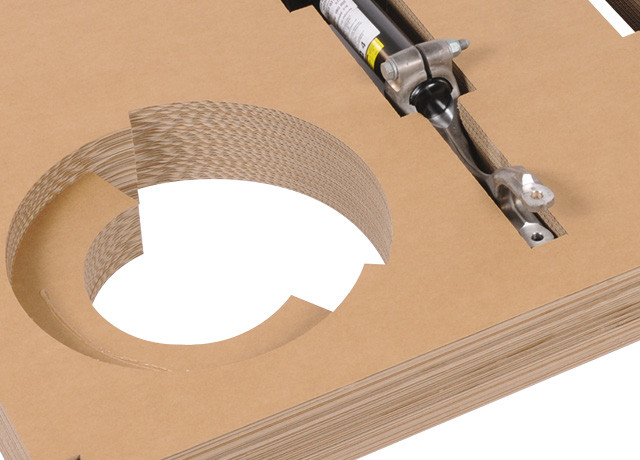

Whether 2-point, 3-point or 6-point packaging, all variants can be produced on our machinery. Dimensions of up to 2,300 mm and grades extending up to the stronger double-wall version can be produced.

Particularly with very heavy parts or where there are high stacking forces, wooden packaging parts can provide the packaging with the strength and rigidity it requires. Wooden pallets with and without IPPC certification are also often an important addition to a packaging concept.

Honeycomb board is noted for its extremely high surface load capacity and therefore for its outstanding load handling. In different profile thicknesses, it can be used as an intermediate layer, die-cut or as padding.

It is often little things that ensure good handling. A wide range of closures, reinforced handles and stacking aids can be used to make packages easier to handle.

Special requirements demand special solutions which can often be realised by providing coatings on the corrugated board. The corrugated board can be provided with an antistatic, corrosion-inhibiting or abrasion-resistant PE coating.

Packaging solutions